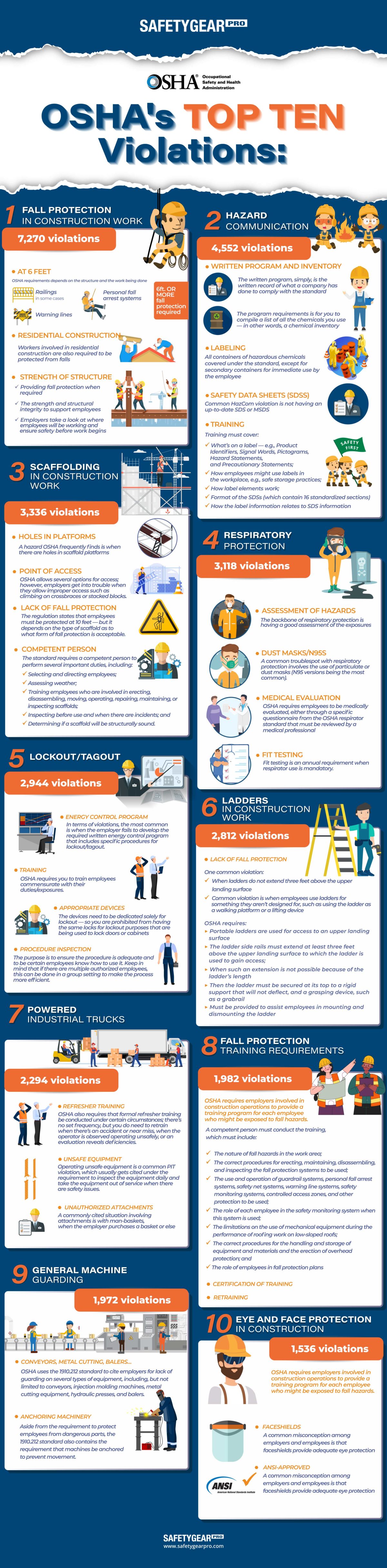

The Occupational Safety and Health Administration is the regulatory agency charged with ensuring that workplaces in the U.S. are reasonably safe. Part of this work includes visiting work environments and inspecting for violations. While there are many possible OSHA regulatory violations, some come up more than others. From failing to issue OSHA safety glasses to having improper communication, the following are the 10 most frequently cited violations.

1. Fall Protection

Lack of proper fall protection has continued to be the number one violation for several years. Any time an employee is in a position where a fall could cause an injury, he or she needs to be wearing appropriate fall protection equipment. Furthermore, heights need to be appropriately secured to minimize the risk of falls. It may be a rooftop, scaffold, ladder or other height. Falling is the leading cause of death in the construction industry. Employers need to take fall protection seriously.

2. Hazard Communication

Next on the list is hazard communication. To create a safe work environment, people need to be sufficiently warned about potential hazards around them. For example, if there is a risk of eye injury, there needs to be a sign indicating this and requiring that OSHA approved safety glasses or goggles be worn. Hazard communication needs to follow specific guidelines laid out by OSHA. The goal of this is to make signage sufficiently standard so that anyone can understand it.

3. Scaffolding

Scaffolding is another frequent citation. Specifically, the design, installation and loading of scaffolding need to be within OSHA’s specifications. However, many construction crews simply erect whatever will work. Unfortunately, this creates an unsafe working condition that could result in serious injury. For example, scaffolding faults may lead to falls or strikes by falling objects. OSHA estimates that 65% of construction workers work on scaffolds. So, this violation category is a particularly important one. Thousands of workplace injuries and dozens of deaths are related to scaffolding each year.

4. Respiratory Protection

Failing to provide and require appropriate respiratory protection is becoming an increasing issue on the OSHA top ten list. A few years ago, this citation was still on the list but in a lower position. However, following the start of the COVID-19 pandemic, these violations spiked because respiratory health became more important than ever. There are lots of respiratory risks including dust, fumes and pathogens. Respiratory protection is challenging because some hazards can get between gaps in masks. Employers need to carefully follow OSHA standards.

5. Lockout/Tagout

Lockout/tagout is a process for controlling hazardous energy stored within equipment. For example, if a piece of machinery is powered by high voltage electrical power, it is important that the access point for servicing the power components be closed, locked and tagged. However, this is another common area that people are overly lax with on job sites. There are numerous deaths every year caused by electrocution. Many of these can be prevented through proper lockout/tagout procedures.

6. Ladders

It should probably be no surprise that another height-related violation is on the list. Although ladders are simpler than scaffolds and, consequently, have fewer violations, they are a very similar problem. Teams use the wrong types of ladders for given situations. Additionally, they may not place ladders correctly for safe use or may exceed the maximum allowable load for a ladder. Another common ladder-related violation is failure to provide proper training on ladder usage.

7. Powered Industrial Trucks

Industrial vehicles such as forklifts, tractors and platform lift trucks have strict requirements about who can use them and how they can be used. They may only be used by trained operators; they need to be regularly maintained; and, they can only be used for their intended purposes. Unfortunately, many worksites fail to follow these requirements. Consequently, people find themselves in dangerous situations around powered industrial trucks. One common violation is using a cellphone during operation, which can be distracting.

8. Fall Protection—Training Requirements

Fall protection is such a major problem that it regularly appears on OSHA’s list twice! The second entry is related to the training requirements for fall protection. Not only do team members need to have the right equipment to keep them safe, but also, they need to have sufficient training on using that equipment and otherwise practicing effective safety standards at heights.

9. Machine Guarding

Proper guarding of hazardous machinery was one of the first major issues related to workplace health and safety (long before OSHA was even created). Despite this, it continues to be a problem today. Machine parts that could cause severe injury needed to be guarded such that employees cannot make accidental contact. Additionally, those team members need to be trained on how to be safe around that machinery. Safeguards are quite simple, but they require careful evaluation of machinery-related hazards.

10. Eye and Face Protection

Eye and face hazards are among the most common in workplaces and some of the easiest to address. Despite this, many employers are cited for not providing and requiring appropriate OSHA safety glasses, face shields and other face PPE. Eye injuries are some of the most common in workplaces. A large majority of them are avoidable by simply using the right equipment. From dust and debris to fumes and chemicals, eye hazards are serious business.

Get the Equipment You Need To Stay OSHA Compliant

Too many employers are out of regulation for the above standards and others. You can avoid joining them by purchasing top-quality PPE, hazard signage and other safety products from Safety Gear Pro. Check out our full catalog today to find the items you need for your workplace. If you are a worker and want to find PPE that is more comfortable for all-day wear, we have you covered for that too.

FAQs

Where Can I Order OSHA Safety Glasses and Other PPE?

You can order personal protective equipment such as safety glasses, hardhats and fall protection from Safety Gear Pro. We provide a wide range of safety products, including many of the items needed to help ensure a safe work environment.

How Can I Get OSHA Approved Prescription Safety Glasses?

Yes, many of the safety glasses at Safety Gear Pro can be equipped with prescription, OSHA approved lenses. Find a pair of safety glasses you like and open the product page. There, select “Prescription Lens” then “Customize Lens.” This will let you enter, upload or send your prescription details.

What Is Personal Protective Equipment?

Personal protective equipment or PPE is clothing, helmets, glasses and other worn equipment intended to protect the user’s body from injury or other harm. OSHA has various standards that describe the proper use of PPE. Additionally, many types of PPE must provide at least a regulated level of protection.

Do Employers Have To Provide PPE?

Employers are required by law to provide a safe work environment. In certain cases, this requires issuing personal protective equipment. For example, if someone is working in a dusty environment, the employer would likely need to provide at least respiratory and eye protection.

What Are the Types of OSHA Violations?

OSHA violations are rated depending on severity. These levels include willful, serious and other-than-serious. Additionally, employers may be cited for de minimis (a non-standard measure that doesn’t impact safety), failure to abate (has not corrected a previous violation) and repeated violations.