A safety harness is the main requirement to ensure a safe working experience in areas where there is a substantial risk of falling. Choosing a full body harness is therefore important for both job safety and to provide a better working experience. But how to choose one? There are many factors that you should put to consideration, such as the risk level of the work environment, the job task, etc.

Here are some considerations to keep in mind before buying one:

1. Application-specific Safety harness

Different types of work environments and tasks require safety harnesses that match the needs of that specific application. For instance, the harness manufactured for welding purposes would feature components like webbing design and heat-resistant fabric. This would ensure that the body of the worker is protected from any splashes and can resist charring and damage. On the other hand, the harnesses that have been designed for climbing are designed to put lesser weight on the worker and come with rescue connections.

2. Environmental conditions

Environmental conditions also play an important role in the feasibility of the harness for a certain job. Take the example of polyurethane-coated harnesses. They are perfect for making sure that the harness remains clean when it comes to messy tasks like tar roofing or oil field work.

3. Worker-specific Safety harness

It is important that the full body harness is able to fit snugly to a worker’s body. This would ensure fall protection for the worker. This is why harnesses are available in various sizes like XS, XL and XXL. A good fit would ensure that the worker remains safe in the case of a fall.

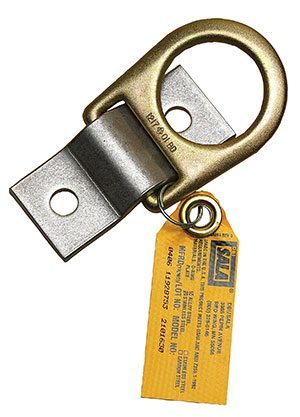

4. D-ring configuration- body harness

The consideration of a D-ring is important because there are some misunderstandings related to it. Some people think that installing more configurations is better and makes the harness feasible for use on many applications. However, more configurations often lead to confusion for a worker.

A D-Ring is usually fitted on the back of a harness, but it depends upon the application. For example, if a worker is using a vertical climbing system, then the harness attachment would be in the front so that the worker climbs easily. Similarly, in the applications where the harness wearer needs to work in a cramped space, the D-ring is configured on the shoulder.

5. Comfort of the wearer

Depending upon the task and the working conditions, additional add-on options for a harness may change. For example, a padded harness may not be comfortable for a user working under high temperature.